PARMACO Metal Injection Moulding AG

Fischingerstrasse 75

CH-8376 Fischingen

Phone: +41 – 71 – 977 21 41

FAX: +41 – 71 – 977 21 22

Email: info@parmaco.com

Web: www.parmaco.com

Quality management: Certificate (PDF)

Representation in Austria since 2011

Burde & CO GmbH

Phone: +43 – 1 – 4023973 – 0

Email: service@burdeco.com

MIM procedure

- The MIM procedure combines the classic powder metal sintering technology with injection molding technology from plastics technology.

- The finest metal powders are mixed with an organic binder system and processed into an injection-moldable mass.

- Subsequent processing takes place in slightly modified injection molding machines into so-called “green parts” = handleable, dimensionally stable parts, but with low strength; these parts are approximately 18% larger than the finished product.

- After demoulding, the parts are again debound. This takes place in a chemical and a thermal step. Then there is a porous part (“blueing”) with relatively low strength.

- The complete conversion into a body with comparable properties of a metal body machined from solid takes place in the final sintering process at temperatures close to the melting point. The diffusion processes that take place lead to a dense metallic body. The associated loss of volume is significantly higher than in plastics processing and is taken into account accordingly in the design.

- In many cases, the parts produced in this way do not require any post-processing. If necessary, all conventional methods can be used (grinding, drilling, coating, electroplating, hardening, etc.).

Applications

- Automotive industry

- Medical technology

- Connection technology

- Precision engineering industry

- Military technology

- Power tools

- Lock technology

- Telecommunications

Advantages

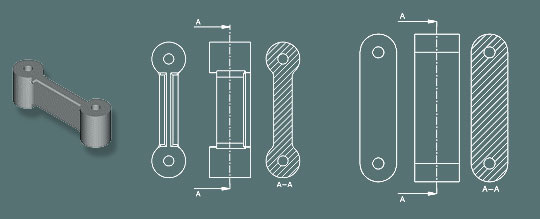

- Production of complex geometries (holes, undercuts, gears, grooves)

- Manufacture of thin-walled components

- very high dimensional accuracy

- high temperature resistance

MIM – classic puller metallurgy

- higher density

- better mechanical properties

- Possibility of complex geometries

MIM – fine casting

- usually no post-processing

- better tolerances

- Production of complex geometries

MIM - fair construction

- wall thickness as uniform as possible

- avoid wall thickness jumps

- radii at transitions

- straight bearing surfaces for sintering

Materials

Alloyed steels

| Material | Nr. | Steel type | Composition (wt%) | |||||

| C | Si | Ni | Cr | Fe | Other | |||

| S 6-5-2 | 1.3343 | high speed steel | 0.95 – 1.10 | <0.45 | – | 3.80 – 4.50 | bal. | W, Mo, V |

| AISI 4340 | 1.6565 | tempered steel | 0.38-0.44 | <0.35 | 1.65-2.00 | 0.7-0.9 | bal. | Mo, Mn |

Properties (sintered)

| Material | Nr. | sintered density [g/cm3] |

Rp0.2 [MPa] |

Rm [MPa] |

A [%] |

hardness |

| S 6-5-2 | 1.3343 | 8.0 | ||||

| AISI 4340 | 1.6565 | 7.4 | >500 | >900 | ca. 9 | ca. 150 HV1 |

Steels stainless

| Material |

Nr. |

Steel type | Composition (wt%) | |||||

| C | Si | Ni | Cr | Fe |

Other |

|||

| AISI 17/4 PH |

1.4542 |

precipitation hardening steel |

<0.03 | <1.00 | 3.0 – 5.0 | 15.5-17.5 | bal. |

Cu, Nb+Ta |

| AISI 316L |

1.4404 |

Stainless steel | <0.03 | <1.00 | 10.0 – 14.0 | 16.0-18.0 | bal. |

Cu,Nb |

Properties (sintered):

| Material |

Nr. |

sintered density [g/cm3] | Rp0.2 [MPa] |

Rm [MPa] |

A [%] |

hardness |

| ISI 17/4 PH |

1.4542 |

>7.6 (>97.5%) | ca. 700 | ca. 820 | ca. 10 |

ca. 300 HV10 |

| AISI 316L |

1.4404 |

>7.6 (>97.5%) | ca.150 | ca. 480 | ca. 55 |

ca. 120 HV1 |

FeNi alloys

| Material |

Nr. |

Steel type | Composition (wt%) | |||||

| C | Si | Ni | Cr | Fe |

Other |

|||

| FeNi2 |

– |

sintered steel | <0.01 | <0.20 | 2 | – | bal. |

– |

| FeNi7 |

– |

sintered steel | <0.01 | <0.20 | 7 | – | bal. |

– |

| FeNi36 |

1.3912 |

sintered steel | 0.01 | <0.20 | 36 | – | bal. |

– |

| FeNi42 |

1.3917 |

sintered steel | 0.01 | <0.20 | 42 | – | bal. |

– |

| F15 |

1.3981 |

sintered steel | 0.01 | <0.20 | 31 | – | bal. |

15% Co |

Properties (sintered):

| Material |

Nr. |

sintered density [g/cm3] |

Rp0.2 [MPa] |

Rm [MPa] |

A [%] |

hardness |

| FeNi2 |

– |

>7.8 (>98%) | 200 | 350 | ca. 26 |

ca. 150 HV1 |

| FeNi7 |

– |

>7.8 (>98%) | 290 | 430 | ca. 26 |

ca. 150 HV1 |

| FeNi36 |

1.3912 |

>7.8 (>98%) | 310 | 480 | ca. 30 |

ca. 140 HV1 |

| FeNi42 |

1.3917 |

>7.8 (>98%) | 300 | 500 | ca. 30 |

ca. 140 HV1 |

| F15 |

1.3981 |

>7.9(>98%) | 380 | 540 | ca. 30 |

ca. 160 HV1 |